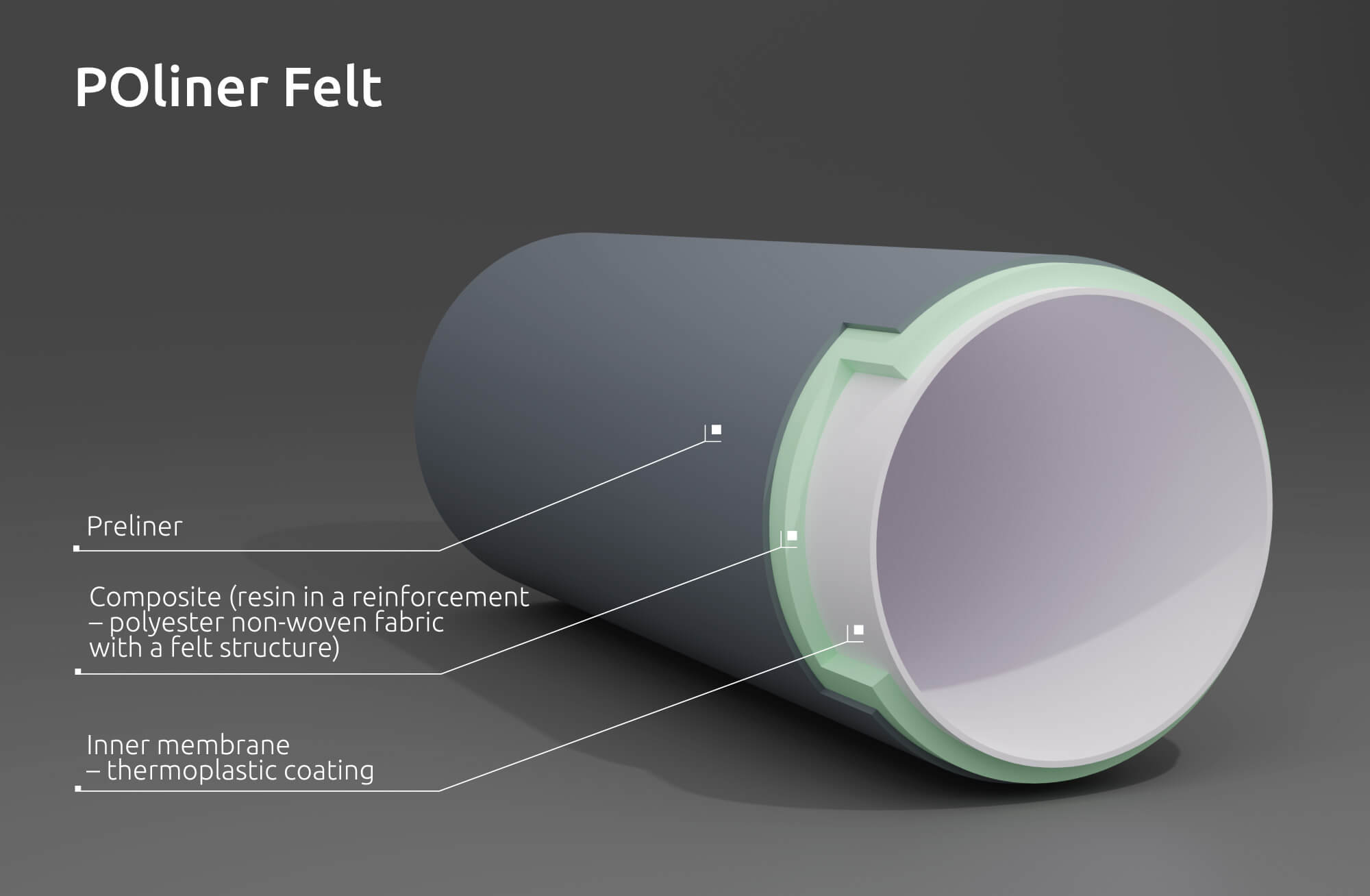

POliner Felt

The information contained on the website www.poliner.eu does not constitute a commercial offer.

As a manufacturer, POliner may change product specifications without notice.

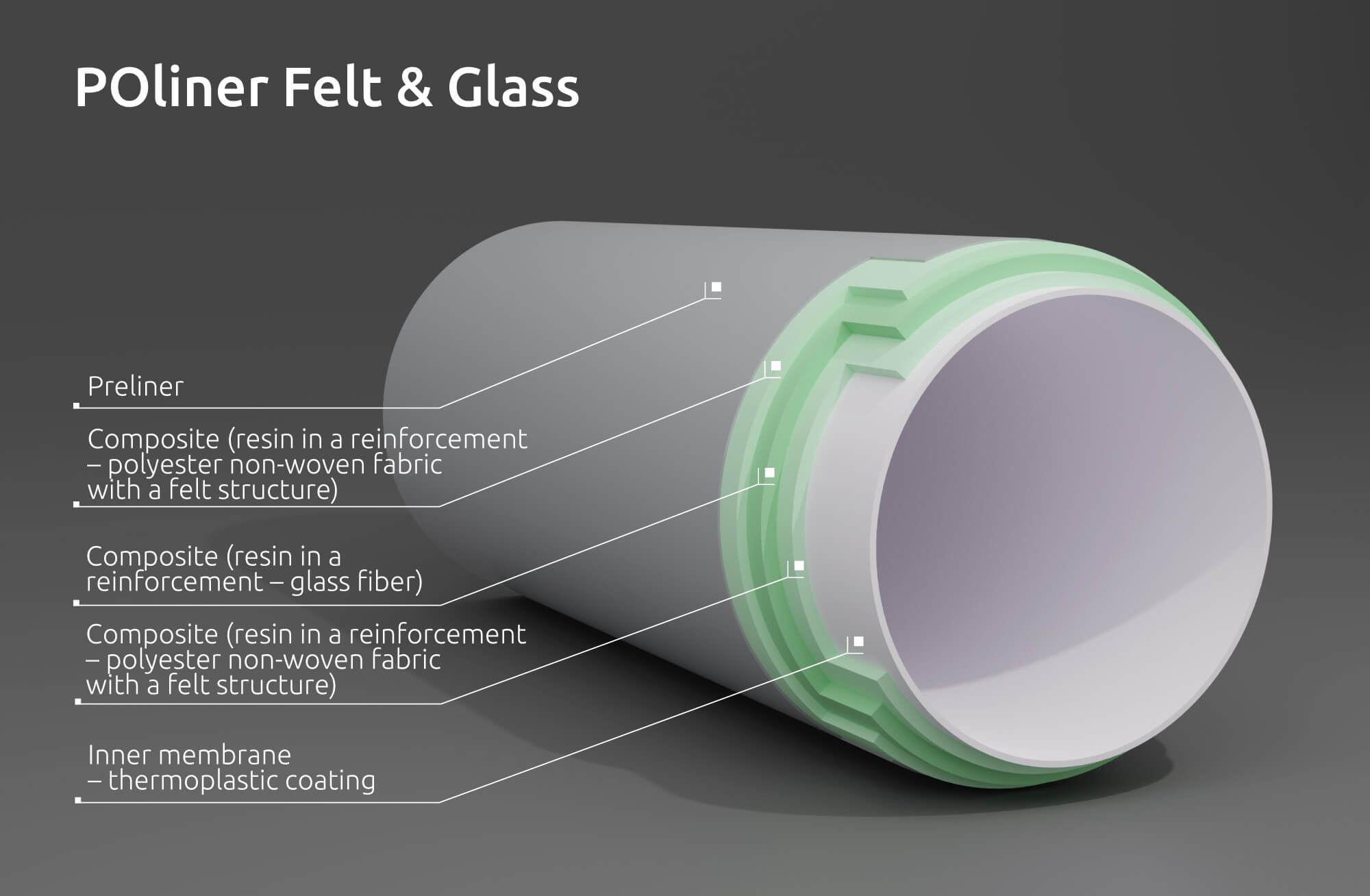

The polyester non-woven fabric with a felt structure, used as a carrier material, ensures high flexibility of the lining and perfect adaptation to the shape of the pipe, as well as the ability to overcome bends. The felt liner is impregnated with unsaturated polyester, vinyl ester or epoxy resin. The resins, after curing process as a final product do not cause any harm to the environment.

The initiation of the copolymerization process is carried out, depending on the resin used, by irradiating the composite with UV rays or thermally.

An attribute of the POliner Felt and Felt & Glass linings is the possibility of their installation inside the pipe through the so-called inversion method. The inversion method allows the CIPP liner to be installed inside the pipe, even in places, where access to the pipeline is restricted. The entire process of assembly and hardening of the liner can be carried out with access to only one well. Considering the specificity and complexity of tasks in the trenchless industry, this feature is a significant advantage.

The number of layers of polyester non-woven fabric is selected in accordance with the strength requirements. In order to achieve more favorable design parameters, the offer includes a product additionally reinforced with glass fiber – POliner Felt & Glass.

| POliner Felt | ||

|

PRODUCT TYPE PARAMETERS |

Felt | Felt & Glass |

| Range | DN150 – DN2000 | DN200 – DN1200 |

|

Wall thickness range PN-EN 11296-4:2011 |

3 mm – 60 mm | 3 mm – 26 mm |

|

Short-term modulus of elasticity (E0) PN-EN ISO 178:2011 |

≥ 2100 MPa | ≥ 5000 MPa |

|

Long-term modulus of elasticity (Ex) PN-EN 1228:1999 |

≥ 1400 MPa | ≥ 3000 MPa |

|

Flexural stress at break PN-EN ISO 178:2011 |

≥ 35 MPa | ≥ 48 MPa |

| Curing process | hot water/steam |

UV hot water/steam |