POliner at the "Trenchless Engineering" Conference. See photos

POliner was the Gold Sponsor of the 20th jubilee edition of “Trenchless Engineering International Conference, Exhibition and Technology Shows “. This largest trenchless technologies industry meeting for Central and Eastern Europe took place on June 21-23, 2022 in Tomaszowice near Krakow.

The conference – traditionally – included 3 days of interesting lectures, providing participants with expert knowledge and many opportunity to discuss topics important for the trenchless industry. This year, the main concern were quality issues in the entire investment process and the opportunities and threats resulting from the fast changing business environment. Experts from POliner, Paulina Stopa and Michał Milczarek, explained the issues related to resins used in the renovation of CIPP, presented the properties of polyester and epoxy resins and discussed trends in their development.

The conference participant had an opportunity to take part in many technology shows and attractions in Tomaszowice. The conference was organized in a hybrid system. Nearly 400 registered participants met on the spot, while over 2,000 unique users decided to use the online version

POliner Glass at a Construction Site in Romania

In the town of Abrud, in Romania, our sister company Blejkan Construct SRL carries out a project of rehabilitating a sanitary sewer. One part of the sewer is being rehabilitated using relining technology, while another part has already been modernized using CIPP UV technology. This latter part used POliner Glass that we delivered to the construction site.

In total, a length of 1266.5 m of POliner Glass, DN500/750 in diameter and 8 mm thick, was installed in the sewer. The project was divided into 20 sections.

POliner is merging with MAZUR!

On 8 June 2021, Mazur sp. z o.o., a company producing CIPP liners and carrying out rehabilitation of pipelines using trenchless technologies, underwent a split and its assets were taken over by members of BLEJKAN Holding Group:

- POliner sp. z o.o. took over the parts of the enterprise responsible for production;

- Blejkan S.A– took over the parts of the enterprise responsible for services, i.e. building works. robót budowlanych.

This means that from that moment onward all of Mazur company’s production related projects and implementations will be carried out by POliner.

This also means, that all payments, accounting documents and other correspondence should be sent to POliner. z o.o.

The merger with Mazur sp. z o.o. is another step in the implementation of BLEJKAN Holding Group’s strategy, for which development is one of the priorities.

Our liners delivered to Elbląg

PWiK Bytom sp. z o.o., a sub-contractor of Instal Warszawa S.A., installed first liners at the Elbląg based wastewater treatment plant. The rehabilitation of two steel pipelines formed part of a project task entitled “Reconstruction and Expansion of a Wastewater Treatment Plant at ul. Mazurska 47 in Elbląg”. The whole scope of works carried out by PWiK Bytom is the rehabilitation of over 1100 m of different-diameter pipelines. The scope also involves pressure sewer lines. PWiK Bytom intends to rehabilitate all pipelines using specialized POliner liners

Since there are curves along the sewer route, the rehabilitation will be made using felt-type liners, known for their high flexibility and very good fit to the shape of any pipe. The specific product that was used was POliner Felt liner (previously called Mazur Liner II) having a diameter of 1000 and 1200 mm, and thickness of 21 mm and 24 mm, respectively. First, a 58.5 m long pipeline carrying activated sludge out of the bottom of a secondary settling tank was rehabilitated, and then a 42.1 m long pipeline transporting treated wastewater from the biological reactor to the secondary settling tank. The liner was put in place using the water inversion method.

On-Site Technical Support

In the center of Kraków, the City of Polish Kings, in a small street named after Ludwik Zamenhof, in May 2021, INVEST-LEX company rehabilitated an egg-shaped, 600/900 mm, combined sewer system.

The above Contractor was selected by Kraków water system company, Wodociągi Miasta Krakowa S.A., and during the installation representatives of POliner and BLEJKAN companies provided technical support.

A POliner Glass UV liner (previously called Mazur Liner UV) was used. The installed liner was 63 m long, had a replacement diameter of 757 mm, and a thickness of 8 mm.

The whole process was carried out smoothly, quickly, and efficiently, thanks to the knowledge and experience of the Contractor’s team and the egg-shaped liner that fit the sewer perfectly, all combined with the provided technical assistance. The entire process started and was completed within one day.

We appreciate the trust vested in our products and expertise, and look forward to more business in the future.

Happy Easter!

On the occasion of Easter, we would like to wish you

the best of health, high spirits, hope and love,

a moment of reflection and plenty of joy at the Easter table with your family.

POliner Team

A Record Year 2020

POliner, the leader on the Polish CIPP liners market, summarized the year 2020. Despite the pandemic and many restrictions, last year was an exceptionally strong year for us, in fact, a record year. We are one of three in Europe and the only in Poland producer of both fiberglass liners and polyester felt fabric liners. Apart from Poland, our liners have been installed in countries such as Estonia, Finland, Israel, Lithuania, Latvia, Romania, Germany, and the Czech Republic

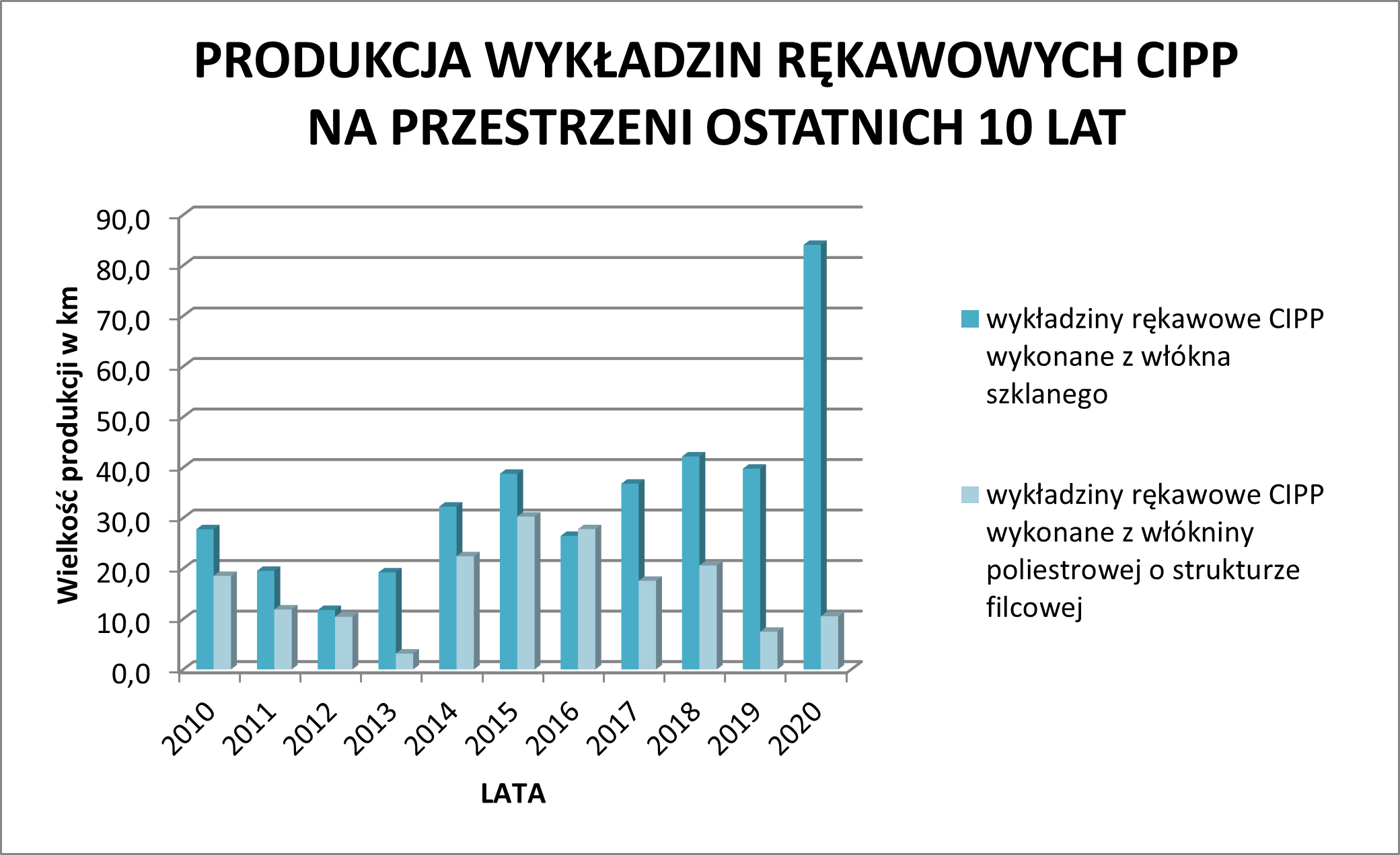

In the past 10 years, we have produced a total of 558.9 km of CIPP liners, of which:

– 378.4 km were fiberglass CIPP liners,

– 180.5 km were CIPP liners made of felt-structure nonwoven polyester fabric.

In total, from 2005 to end of 2020, we produced 699 km of CIPP liners.

Our professionalism, knowledge, technical facilities and personnel potential have allowed us to improve the effectiveness and efficiency of the production process while reducing its costs, which has led to the optimization of production. This is best evidenced by the production volume we reached in 2020, which is more than two and a half times higher than in the best years in the past. Below is a chart showing how production volumes have evolved in the past 10 years.

Thanks to the research and development works that we have been conducting for over a year we have managed to obtain a Hygienic Certificate from the Polish National Institute of Public Health, National Institute of Hygiene (Państwowy Zakład Higieny) for the CIPP liner designed specifically for trenchless rehabilitation of water supply pipelines using the on-site curing method, including in systems for the supply of water for human consumption.

Another equally important document that we managed to obtain, confirming the highest quality of our products, is the National Technical Assessment issued by the Polish Building Research Institute (Instytut Techniki Budowlanej), which gave its positive assessment of the functional properties of CIPP liners for trenchless rehabilitation and sealing of gravity and pressure sewers, and water supply systems.

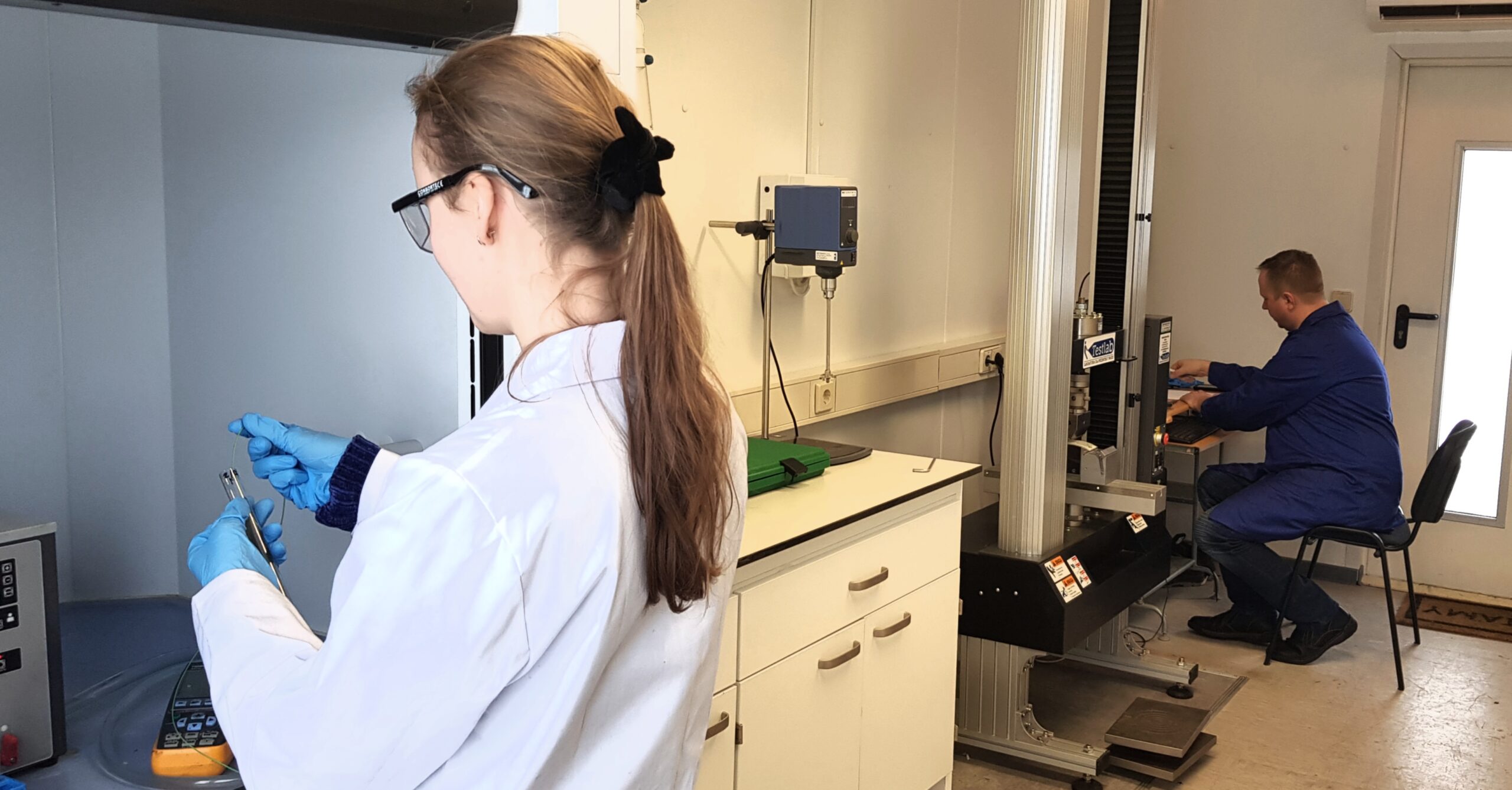

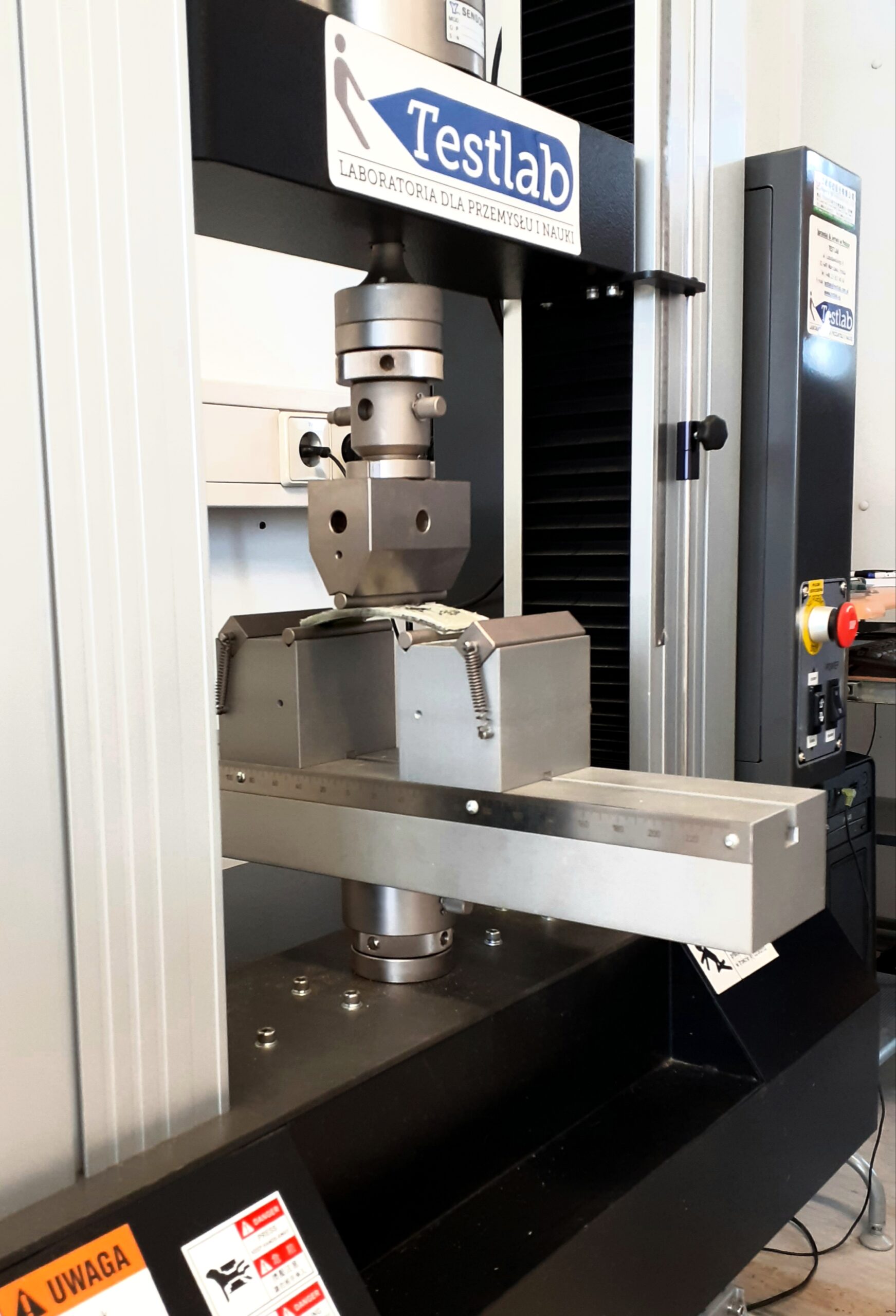

Test Laboratory

We would like to inform you that since January 2019, a professional testing laboratory has been operating in our company, established under the project below:

The project entitled „Building a professional R&D department as support for the development of innovative products of POliner” under the Regional Operational Program of the Lower Silesian Voivodeship 2014-2020 co-financed by the European Union, European Regional Development Fund/European Social Fund.

Project objectives: building a professional research and development department, testing laboratory, this will allow us to constantly expand the range of provided services by developing innovative solutions in the industry.

Planned outcomes: development of three innovative products with significantly less environmental impact and characterized by higher durability compared to products used so far.

Project duration: 2 October 2017 – 31 December 2018

– project value: PLN 431,177.66

– contribution of European Funds: PLN 110,452.76

Our laboratory continuously checks raw materials and oversees the quality of all products being manufactured. We provide laboratory testing services for pipe and rehabilitation liner testing. Our services are aimed at investors, manufacturers of materials for renovation of underground infrastructure, as well as building works contractors. We also welcome individual customers to do business with us.

The laboratory determines flexural properties of materials and the initial specific ring stiffness according to the scope and methods given in current Polish and international standards:

- PN-EN ISO 178:2011 + A1:2013-06: Plastics – Determination of flexural properties;

- • PN-EN 1228:1999 Plastic piping systems. Glass-reinforced thermosetting plastics (GRP) pipes. Determination of initial specific ring stiffness.

The laboratory must work in compliance with the regulations of the Integrated Management System, and the lab’s management system.

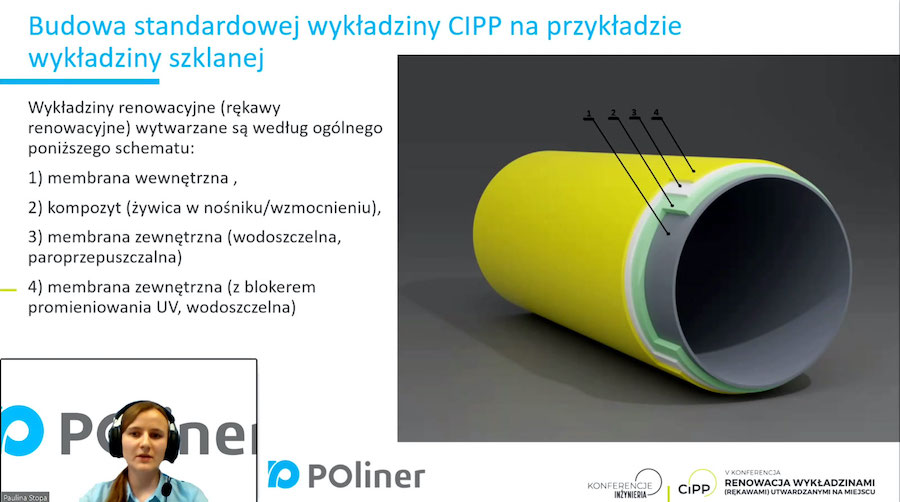

We were the Gold Sponsor of the 5th conference “Rehabilitation with Cured In-Place Pipe Liners”

On 20-21 January 2021 we had the pleasure of taking part in the 5th Conference “Rehabilitation with Cured In-Place Pipe Liners”, of which we were the Gold Sponsor. During the event, which was held 100% online, attendees could listen to a paper entitled “Quality control of fiberglass CIPP liners on the example of the products by POliner sp. z o.o.”, which was presented by Paulina Stopa, our company’s representative, as well as learn our offer at the virtual exhibition stand.

The program of this year’s Conference included 14 papers and three discussion panels, during which we talked about such issues as quality control of renovation liners, resins and curing methods, testing of CIPP liners, and guidelines for acceptance of rehabilitation works that use CIPP technology – which are being developed by the Polish Association of Trenchless Technologies. Discussion also focused on significant new products and technologies which appeared on the market over the past year and their changes, as well as interesting implementation projects.

Multimedia shows held in between the sessions were an additional attraction.

Together with the Organizers, we would like to thank the Participants for taking part in the event.

A full photo gallery and coverage of the Conference at: http://bit.ly/relacja_CIPP2021

Merry Christmas and a Happy New Year!

Holidays are getting closer! On this occasion, we wish you and your families happy Christmas time, filled with joy and peace. May this wonderful Holiday time be full of warmth, relaxing family atmosphere, and the upcoming New Year bring you prosperity and success to all your personal and professional goals.

The Poliner team